The approach Andy continues to practise is rooted in some lessons that were learned in Toyota’s Supplier Support Centre (TSSC).

In the early 1990s, Toyota’s international reputation was growing because of how it had designed and was operating its own facilities. TSSC was the part of Toyota which was grappling with how to help suppliers to achieve similar benefits, but this meant accomplishing deep change across entirely different organisations. This posed severe change-management challenges as well as the technical ones: inertia had to be overcome and established patterns of thinking had to be overhauled if managers and their workforces were to achieve irreversible transformation together.

Andy has now been practising the approach for twenty years, since he first witnessed how much sustainable improvement could be delivered to a unique organisation so quickly. Through working out many similar transformations in diverse industrial operations around the world, Andy continues to learn why the approach works and how to apply it to best effect. Success depends on blending three ingredients: a practical, narrow-and-deep change process; insightful redesign and leadership coaching. In each of these areas there are popular reasons for choosing alternative courses, that can lead to common pitfalls. Therefore, in his first training resource – The Incredible Transformation of Gregory Todd – Andy saw the need to warn readers against some of these pitfalls, before providing a sense of what it looks like to successfully navigate the approach and to achieve sustainable transformation.

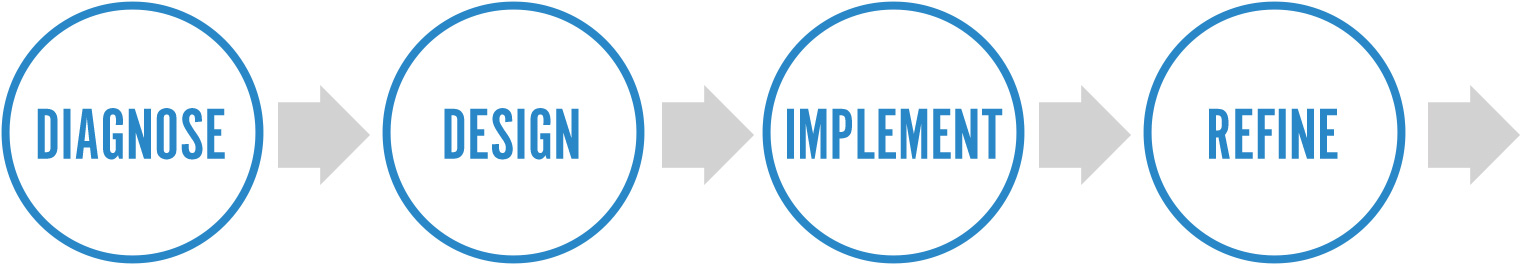

A simple, intuitive, change-management process provides a catalyst for positive, creative change. It should be memorable and focus everyone on how they will be engaged through a fair, logical approach. If people are to think differently as well as to behave differently, deep engagement and coaching will be required. Therefore the scope needs to be narrowed to suit the level of facilitation that can be practically resourced. To fulfil potential, the scope should also be “narrow” in the sense of being defined with (and not across) the natural flows of an organisation’s processes. For example, to transform a manufacturing facility Andy often advocates applying the four phases over a four-month period to transform the fulfilment of orders across the business for one set of products. The benefits of such a change-management process can be illustrated by contrasting them with some pitfalls from alternative approaches, which should be avoided:

The backbone of a transformation is an insightful design that should make clear to most how the organisation can better achieve its purposes. This can be achieved through redesigning the chosen section of the organisation systematically, solving the root causes of problems that may only emerge downstream. Practical, insightful capability is required, which may need to be specific to that type of organisation. Then the most significant problems can be diagnosed and solved without jargon, while also enabling the organisation to make the most of its unique opportunities. For example, in Andy’s specialist field of redesigning manufacturing operations, relevant principles from Toyota’s Production System need to be applied, but he tries to avoid “lean manufacturing” terms. This helps to cut through the minefield of lean misunderstanding, so he can explain in everyday language his diagnosis of the particular keys that will collapse waste in each unique facility – and how the most can be made of specific business opportunities. The associated benefits are easier to appreciate when contrasted with some further pitfalls that should be avoided:

Most leaders will not previously have attempted deep, wholesale change: in which the majority of their organisation will be required to change the way they think and work. Therefore even experienced leaders stand to learn from those who have been through similar initiatives. A successful transformation leader will be one who can be coached to rise above the limitations of managing or supporting the transformation, in order to lead their organisation through it. A transformation initiative will also stress and strain an organisation like never before, so its leaders will need to prepare their people to coach, support and strengthen each other. For example, the transformation is likely to expose managers who are reticent to take initiative, embrace problems, or trust others who are better placed to make decisions. In this way, leaders can take full advantage of the initiative and precipitate cultural transformation, beyond the transformation of performance. Without good coaching, leaders may miss this opportunity and unwittingly allow their initiatives to fall into the following pitfalls which should be avoided: